What are the key points to pay attention to when customizing hotel lighting from design to installation?

2023-09-20 13:00

What are the key points to pay attention to when customizing hotel lighting from design to installation?

With the increasing demand for personalized customization of hotels in the market, it is difficult to find personalized lighting fixtures that are very suitable for hotel needs in the general market. Therefore, hotels will consider their own actual situation and require lighting design companies to customize engineering lighting that is suitable for the hotel environment. What factors should hotel engineering lighting pay attention to?

1. Lighting brightness and style required by hotel environment

According to the hotel's environmental design, it is suitable for the hotel's lighting brightness and the general interests of hotel customers. Proper lighting facilitates the hotel's work, while also providing them with a good atmosphere, making users feel at home and allowing them to stay in the hotel next time.

2. The selection of lighting materials when customizing hotel lighting.

Using low-power LED chips as the light source, the service life of hotel engineering lights is longer than that of ordinary light sources. At the same time, when the room temperature is 45 ℃ and the chip temperature exceeds 65 ℃, the service life of the lamp will be greatly reduced. Therefore, it is necessary to have strict requirements for the materials of the lamps used. Luminaires made of inferior materials may not show any shortcomings in the short term, but long-term use can lead to problems such as rust, discoloration, yellowing, and light decay. The material requirements will determine the customization of the luminaire.

3. Price factors for customizing hotel lighting.

The prices of lamps of the same grade are basically the same, but due to different manufacturing processes from manufacturers, there may be some deviation in prices. However, if the price of the lighting fixtures is too far from the market price, there will definitely be a gap in making such lighting fixtures. When customizing hotel lighting, it is necessary to choose a lighting manufacturer with integrity, strength, and good reputation.

4. Customized lighting safety for hotel lighting.

Because hotel lighting fixtures are usually customized, especially in hotel lobbies, the lighting fixtures are large and the weight must not be too light. The safety of lighting fixtures is a key factor, and the load-bearing capacity of installed components is a crucial part.

In short, the main purpose of customizing hotel lighting is to customize appropriate lighting based on the comprehensive factors of the hotel, control the quality of lighting, and achieve good budget control.

Basic inspection standards for hardware blanks of hotel crystal lights

(1) Stamped and spun parts:

1. Material: South Korean plate is preferred, ensuring no sand holes after polishing and a smooth surface after electroplating.

2. Material: No pinholes, bumps, scratches,

3. Thickness: According to the requirements of the engineering data (① 0.6 material for the lamp cup; ② 0.8 material for circular chassis below 400, 1.2 material for 400~800 above 1.0800~1000, and 1.5 material for 1200 (in blocks); ③ Bell type with a material of 0.8 or more.

4. Surface: No spinning marks, stamping marks, or fracture marks. (If this phenomenon occurs, it can be removed after polishing and can be accepted)

5. Surface: No sharp edges; Burrs, burrs.

6. Size: Generally, the tolerance of the workpiece should not exceed ± 1.5MM; Except for special workpieces.

7. Hole position: cannot deform, and the tooth hole must be smooth; If the hanging bell needs to be tested on the hanging rod and welded at the socket, all socket teeth must be tested.

8. Other specific specifications; Size; Aperture; Hole spacing; According to the requirements of the engineering data.

(2) Box:

1. Material: Authentic South Korean plate is preferred, ensuring no sand holes after polishing and a smooth surface after electroplating.

2. Thickness: According to the engineering data requirements (0.8 materials below 400, 1.0 materials above 400~800, 1.2 materials between 800~1000, and 1.5 materials above 1200 (in blocks))

3. Surface: No sharp edges or burrs; No pinholes, bumps, or scratches (within 1 square centimeter, there should be no more than 1 L=2MM bump or scratch, and no obvious areas should be visible; pinholes should not exceed 3 per 1 square centimeter).

4. Welding point: firmly welded; The welding marks on the front of the plate should not be too obvious.

5. Dimensions: The specific dimensions shall strictly follow the engineering data, with a general tolerance of ± 2MM (excluding special workpieces).

6. Hole position: aperture; The hole spacing strictly follows the engineering data, with a general tolerance of ± 1MM (except for special workpieces).

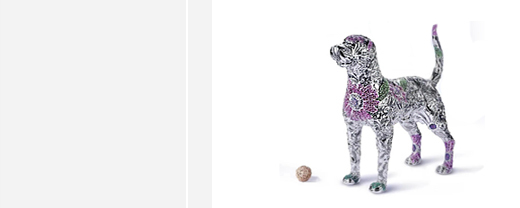

Customized crystal lamp

(3) Management:

1. Material: White material (South Korean material preferred, Taiwan; Japan); After polishing, there are no sand holes, and the surface is smooth after electroplating.

2. Thickness: 0.9-1.0MM (depending on usage); Uniform thickness.

3. Surface: There should be no welding seams or embossed patterns; There should be no sand holes or scratches. (If there is polishing, it must be able to be removed)

4. Blanking: The cutting section must be flat and perpendicular to the straight edge of the iron pipe, and the edge must be small.

5. Chamfering: The chamfering angle shall be determined according to actual needs, and there shall be no reverse edge.

6. Drilling: The hole must be round and there must be no sharp edges on the inside and outside; The aperture and spacing of holes shall strictly follow the engineering data; General tolerance ± 1MM (excluding special workpieces).

7. Hole expansion: The hole must be straight; Ensure the concentricity of the inner and outer circles; There cannot be a cape.

8. Tooth tapping: Before tapping, it is generally required to have a smooth surface and chamfer; Tooth diameter according to requirements; Good dental texture and path; The surface of the inner dental canal should not have dental marks; Be sure to test your teeth.

9. Bend: natural curvature; The pipe at the bend must be full and not flat; No defects such as dents, pits, inflection points, or deformations are allowed; Compared to the engineering drawings, the tolerance for radian is generally ± 1MM (except for special workpieces); Electroplating, baking paint

Selecting Non-Standard Customized Lights: Key Considerations and Issues

Introduction:

In today's world, lighting plays a vital role in enhancing the ambiance and aesthetics of our surroundings. However, sometimes standard lighting solutions do not suffice the unique requirements of spaces. This necessitates the selection and installation of non-standard customized lights. While the idea of tailor-made lighting may seem exciting, there are several crucial factors and issues that need to be carefully considered to ensure optimal functionality, safety, and satisfaction with the end result. In this article, we will delve into the important considerations when choosing non-standard customized lights.

1. Define your Lighting Requirements:

Before embarking on the journey of selecting non-standard customized lights, it is imperative to clearly define your lighting needs and goals. Determine the specific purpose of the lighting installation, whether it is for decorative, functional, or ambient purposes. Consider aspects like light intensity, color temperature, and beam angle requirements to achieve the desired effect.

2. Expert Consultation:

To ensure a successful lighting project, it is highly recommended to seek professional guidance from lighting experts or consultants. They possess the knowledge and experience required to assess your specific needs, propose suitable lighting solutions, and provide expert advice on customization options. Their expertise will help you avoid potential pitfalls and select the most appropriate non-standard customized lights.

3. Quality Assurance:

When it comes to non-standard customized lights, quality is of utmost importance. Ensure that you select lights from reputable manufacturers or suppliers who comply with relevant industry standards and regulations. Opting for high-quality components and materials will not only enhance the longevity and performance of the lighting, but it will also provide greater peace of mind regarding safety and reliability.

4. Customization Options:

One of the primary advantages of non-standard customized lights is the ability to tailor the lighting solution to precise requirements. Take advantage of the various customization options available, such as size, shape, color, and materials. Consider the design elements and existing décor of the space to ensure a harmonious integration of the lighting solution. Collaborate with manufacturers or suppliers to create bespoke lighting fixtures that reflect your unique style and preferences.

5. Maintenance and Support:

Consider the long-term support and maintenance requirements of the non-standard customized lights. Discuss maintenance schedules with the manufacturers or suppliers and inquire about the availability of spare parts for future replacements or repairs. Opt for lighting solutions that come with comprehensive warranties, as it will provide peace of mind in case any unforeseen issues arise.

Conclusion:

Selecting non-standard customized lights can transform any space and create a unique atmosphere that perfectly caters to your specific requirements. By paying close attention to the factors mentioned above, such as defining your lighting needs, consulting experts, ensuring quality and customization options, prioritizing energy efficiency, compatibility, budget constraints, safety, as well as maintenance requirements, you are well-equipped to make informed decisions. Remember, a successful customization process results in well-suited lighting that not only meets but surpasses your expectations, elevates the overall ambiance, and brings your desired vision to life.

Get the latest price? We'll respond as soon as possible(within 12 hours)