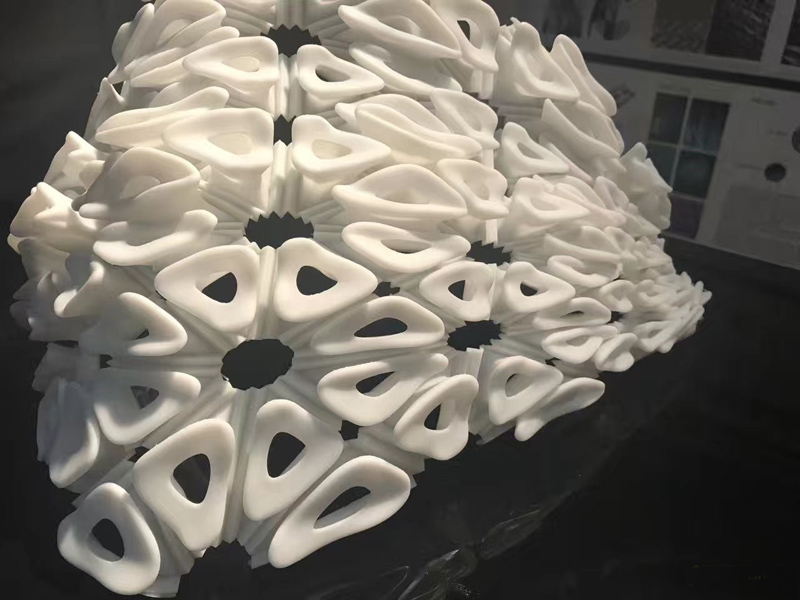

3D printing opens up a new era for lighting field

2023-01-02 13:00

New technologies are slowly emerging. Of course, 3D printing is indispensable. This technology has been applied in many fields, especially in aerospace and automobile industries. 3D printing equipment and materials have become more and more common for mass manufacturers.

The application of 3D printing in lighting field is also developing rapidly. The main reason why lighting and 3D printing can be combined is that lighting designers who can realize product customization and innovation.

At present, 3D printing technology is used for hotel customized chandelier design and LED research and development. It mainly involves two aspects: Parts and components of lighting products can be assembled by 3D printing technology. And lamps designed by designers can be quickly verified by 3D printers, But also can create different types of lighting systems. In the past, manufacturers wasted resources due to mass production. 3D printing can help manufacturers by reducing the purchase quantity of fixed devices and parts, printing them when needed, manufacturing on demand, avoiding waste and saving costs.

In addition, 3D printing can also help reduce the carbon footprint, as long as it is designed by computer and distributed to local manufacturing sites for printing through network/cloud, without having to manufacture lamps all over the world. Therefore, 3D printing plays an important role in lighting.

Get the latest price? We'll respond as soon as possible(within 12 hours)